Whether it's landfill waste, the by-products of manufacturing, or even wasted space, these people have come up with ingenious ways to use up the resources that would otherwise be squandered.

Bioplastics from human waste

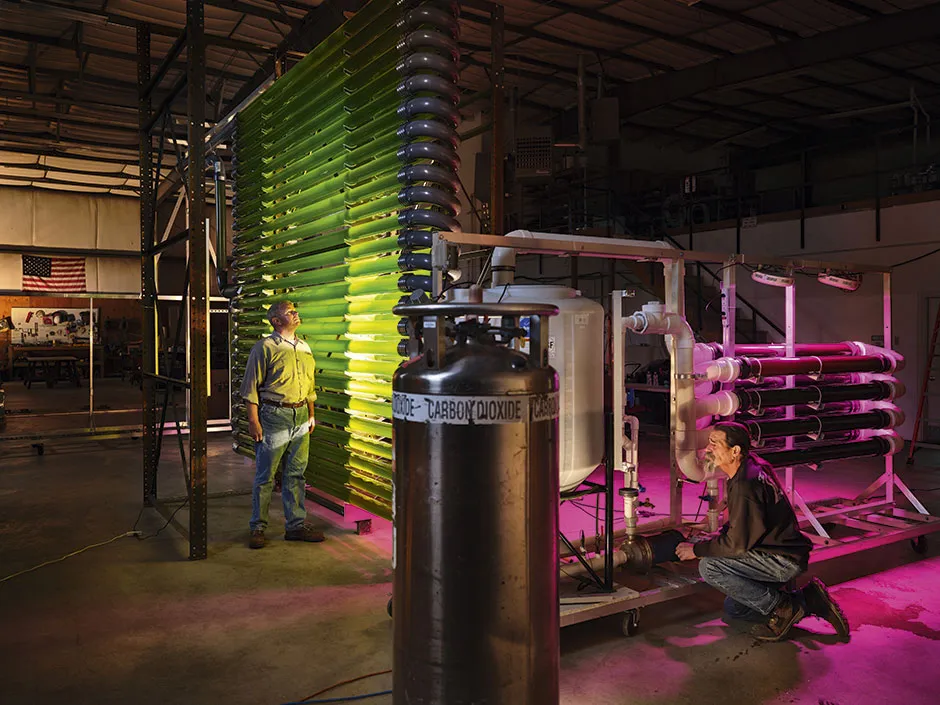

The contents of your toilet is precious – to algae, anyway. Human waste is packed with phosphorus and nitrogen, nutrients that algae needs to grow. Researchers have developed bioreactors, like this machinery designed by ClearAS in Missoula, USA, that exploit the way that algae grows rapidly when exposed to human waste.

The system is packed with algae that extracts nutrients from wastewater, therefore cleaning the water to ensure it meets industry standards. The algae is then used to make materials for bioplastics and bioenergy.

A full-scale system is up and running at South Davis sewers in Utah, treating 18 million litres of water daily.

Storing CO2 in rocks

Geothermal power plants, which use heat from the Earth’s core to generate energy, may provide a steady stream of electricity, but they’re not entirely clean. They produce some emissions – mostly CO2 released when hot water is pumped up from carbonate-containing rocks.

However, at this well (one of over 100 at the Hellisheiði power plant in Iceland) CO2 can be returned to the rocks by adding it to water that is reinjected back into the ground after energy production. Scientists once thought this ‘remineralisation’ process took hundreds of years, but a 2016 study showed it is rapid – working within a year or two to lock the CO2 away. Iceland’s CO2 emissions from geothermal energy are low, but remineralisation keeps the environmental impact to an absolute minimum.

Plants from volcanic energy

Iceland’s Svartsengi lava field might seem a bizarre setting for biotech, but beneath the barren landscape in this image is a vast stream of power. As you can see in the background, steam vents from the ground, a visible sign of Svartsengi’s volcanic energy.

The region is literally “sitting in boiling water” explains Björn Örvar, chief scientific officer at ORF Genetics, whose 2,000m2 carbon-negative greenhouse (front and centre in this image) gets its heat and electricity from the nearby geothermal power station. Inside, 130,000 genetically engineered barley plants thrive year-round in a temperature-controlled, soil-less environment.

Rather than using fertilisers that leave harmful by-products, the researchers supplement the crop with minerals from volcanic ash, and bathe the barley in light wavelengths that are specially tailored to plant growth. From the plants, scientists extract human Epidermal Growth Factor and other growth factors destined for stem cell therapies, skin treatments and lab-grown meat.

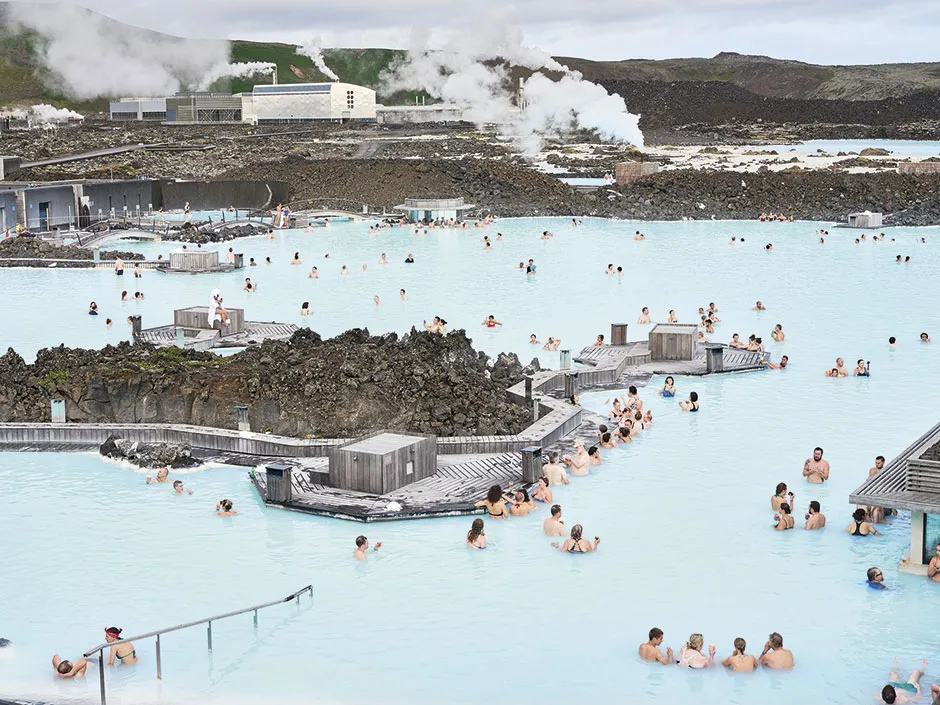

A lagoon from waste water

Due to its large geothermal resources, Iceland makes more energy than it can use. Here, water left over from geothermal power production is allowed to pool in the Blue Lagoon at a soothing 39°C. The lagoon itself is a happy accident.

Water used to drive turbines at Svartsengi power plant is brought up as steam (240°C) from deep boreholes. It is so hot that to avoid destroying the turbines it has to be cooled with cold water – cold water that becomes hot waste water. Originally, when this water was released at the surface, workers thought it would seep into the ground, but it didn’t.

“They threw the hot water here in the lava and slowly, a lagoon started to develop,” explains Örvar. Silica gives the water its blue hue, along with species of blue-green algae that live in it.

Homes from rubbish

The starship Earthship Ark was the setting for 1970s Canadian sci-fi series The Starlost. In the series, the Earthship Ark was a spacecraft the size of Sicily on a mission to colonise far-flung planets. In real life there are less fantastical Earthships, but they still aim to be self-sustaining, just like the Earthship Ark.

US architect Michael Reynolds is credited with the idea of building affordable homes called ‘Earthships’, which are made from reclaimed or natural materials. His company, Earthship Biotecture, now offers training in constructing Earthships.

The ideal Earthship collects rainwater, harvests energy from the wind and Sun, stores heat in the walls and floors, and holds space for growing food. Here, workers in Taos, New Mexico, build an insulating wall from old tyres. Other building materials can include mud, dried grass, bottles and cans.

Packaging from mushrooms

Scientists are always searching for sustainable replacements for plastic. At Ecovative Design in Green Island, New York, the solution – a gnarly-looking material that grows itself – is not what you might expect.

Lightweight and compostable, Ecovative’s patented technology is based on mushrooms. The cream-coloured material pictured here is formed from a fungal network called a mycelium, which grows on farm waste, such as the hulls from cotton seeds. In this picture, a researcher carries out a 3D scan to check its density.

Structures for everything from clothing to car parts can be formed using moulds that shape the growth of the fungi. In the UK, Magical Mushroom Company uses the technology to transform corn husks and hemp into compostable packaging that can be grown to order in just seven days.

A ski slope in wasted space

CopenHill, a giant, asymmetric building incorporating a super-efficient waste-to-energy plant, was completed in 2017, looming large over Copenhagen. In 2018, the plant burned 443,000 tonnes of waste, producing 1.25 terawatt hours of energy – enough to keep your phone charged for 463 million years.

The following year, the bosses at the energy plant got a little crazy. “Hey,” they thought, “let’s build a ski slope on that architecturally impressive roof! And a climbing wall! Why waste the space, huh?”

Almost nothing seems goes to waste at this multifunctional facility. Even the bottom ash from the incineration process is used to make road-building materials. The hope is that by supplying heat and power to nearly 150,000 local homes, the plant should help the city reach its goal of becoming carbon neutral by 2050.

Fertiliser from insulin production

One company’s trash is another’s treasure at the Kalundborg Symbiosis park in Denmark, where companies collaborate to save resources. The Novo Nordisk facility pictured here makes half of the world’s insulin – used in diabetes treatment – through engineered yeast. Its would-be waste, ethanol and gærfløde (yeast ‘cream’), are instead used in biogas and fertiliser production. In this image, an operator checks a pressure gauge while equipment is steam sterilised.

Also at the park is a power plant that was recently converted from coal-fired to biomass-fired: it runs on wood chips, supplying steam for industrial uses and heating for local homes and other on-site businesses.

“The main principle is that a residue from one company becomes a resource at another, benefiting both the environment and the economy,” explains Michael Hallgren, senior vice president at Novo Nordisk and chairman of Kalundborg Symbiosis. He claims the partnership saves over 635,000kg CO2 and £21m in business expenses every year.

- This article first appeared inissue 360ofBBC Science Focus Magazine–find out how to subscribe here