In a few words, what do you study?

I’m a mechanical engineer. Typically, you think of mechanical engineers as people who build machines or devices that use materials like metals or ceramics or plastics. I essentially add another set of materials into the toolbox and think about whether we can start building machines using biological materials like living cells.

So, one example of a biological machine that I built is a robot that uses living skeletal muscle to move and walk around. Machines that incorporate biological materials can do pretty interesting things.

When you fall and cut your skin, you heal. When you exercise, you get stronger. And it turns out that these robots can do the same thing. When they exercise, they can get stronger and they can also heal from damage.

What do you use these biohybrid machines for?

A lot of what we are trying to achieve is just to discover what the design rules and principles of building with biological materials are. For example, building a car is a complex mechanism, but for the most part, most trained mechanical engineers can do all or some part of that.

They know that approximately this stiffness of a steel beam is going to take this much force, or a motor they construct in this way is going to produce this much energy and consume this much energy. We have all of these numbers kind of in place, and getting those design rules and principles in place took us thousands of years.

Read more about robots:

So, a lot of what I’m trying to do in my initial work is to establish what the rules and principles are for building with biological materials. And my focus is to think about whether we can make robots as implantable devices that integrate living biological materials with our bodies.

Then they would be able to do things like sense what’s going on in an individual system, in response to, say, a disease and adapt to their environment in the way that biological materials do.

What benefits do biological machines have over a machine made of metal and plastic that can learn from its environment through, say, artificial intelligence?

You know, I think there’s a place for innovation using lots of different kinds of materials. There are some places, for example, inside the body in particular, where there’s a strong case for using biological materials because they’re designed to optimally function in that environment. These materials are soft, they function really well in 37°C human environments, and operate at the same pH of that particular environment.

They also have all of these adaptive capabilities that synthetic materials don’t have. Certainly, we’ve gone some way with synthetic materials.There are some composite materials that, if you scratch them, might be able to seal that scratch. But it’s never as strong as it was before. And if you repeatedly scratch the same spot, it gets worse and worse and worse, which doesn’t happen to your skin.

You might have fallen and hurt your knee when you were five. If you did that again now, maybe it would take a little bit longer, because we’re all a little bit older, but it’s still going to heal and it’s going to return the skin to its original condition, which it wouldn’t necessarily do in some of those kinds of materials.

And similarly with AI [artificial intelligence], we made a tonne of progress in being able to develop machines that can process lots of different signals, compute a pretty complex response and maybe even learn or adapt.

But we’re still very, very, very far from what the human brain, or brains in general, can do in terms of processing all the different types of signals and making complex decisions or functional behaviours. So I think there’s a place [for biohybrid machines].

My interest lies in implantable devices. What can I put inside the body that’s safe, that can adapt to its environment, and that I can engineer in some way to have a predictive functional response? I still think there’s a strong case to be made that biological materials are your best answer.

What sort of biological materials do you use in these machines? Is it living tissue, like you’d find in a human body?

Kind of similar. So let’s use the example of a walking robot. When we were trying to make skeletal muscle that acts as an actuator that makes this robot walk, we designed something that almost looks like a rubber band.

So we have this sort of mould or a 3D printer and we pattern cells and a mixture of different proteins that mimic their natural environment into this ring-like shape. And what this looks like, at that point, is like if you’ve ever made any kind of gelatine-based dessert or jello [jelly], it’s kind of right before it’s about to gel. It’s like this gooey mixture.

You can pattern it into a bunch of different shapes and then it sets. And that’s the same thing that happens with these tissues. They essentially set into this ring-like shape.

Then, because the cells are alive, when they go through this process, they’re sensing and responding to their environment. Let’s look at the way skeletal muscle works in our bodies. There are individual cells that fuse together to form these long fibres or muscle fibres. That muscle fibre is what’s generating force and producing motion.

When we stack a bunch of those in parallel, like in our legs or arms, we can generate pretty large forces. So we can do the same thing with these tissues. What happens is the cells proliferate. They reproduce. They get in touch with each other in this ring-like construct, and they fuse to form fibres within that construct.

Read more about future technology:

- Future technology: 22 ideas about to change our world

- 57 cool gadgets: our pick of the best new tech for 2020

They essentially remodel their environment and then create the tissue that can generate force and produce motion. And once you get to that point, you can essentially take that muscle ring – which is contractile, or can produce force in response to a stimulus – and you can put it around a skeleton, which is really just like a flexible exoskeleton that can produce different types of motion.

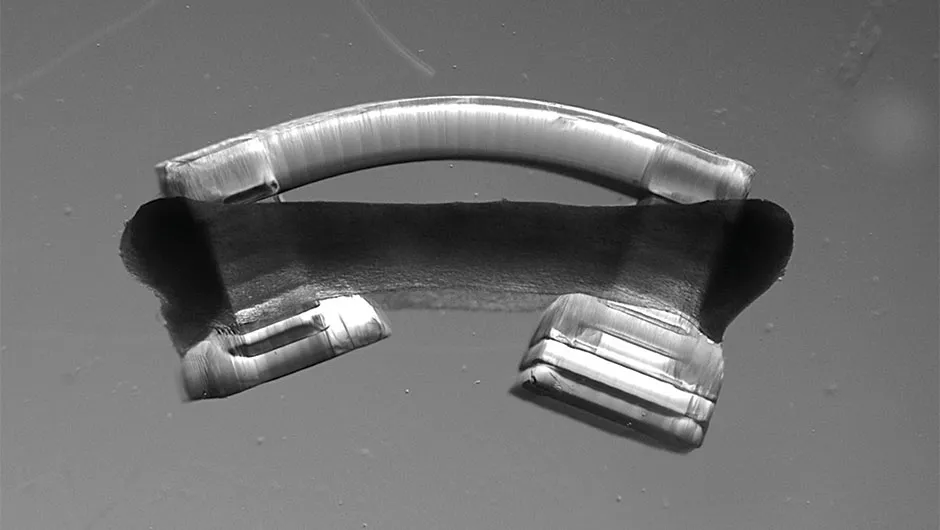

So we focus on something that has two legs and a flexible beam between them, and around those two legs we wrap this muscle. Every time the muscle contracts, it’s able to deform that skeleton and the robot inches forward, kind of like an inchworm. It walks or crawls across the surface.

What else might you use biohybrid design for? Is it all medical?

No, I certainly don’t think it’s all medical. My personal interest is medical, and so I focus on a lot of those applications. As a result, most of the time when I build with cells, I build with cells derived from mammals, because we are mammals and they function in the environment that we’ve created.

However, there are a few other people working on biohybrid design, and there are folks that focus on a lot of different types of materials. They might use cells derived from insects, for example, which actually function pretty well at room temperature but they also function really well even in air, so they don’t necessarily always need to be immersed in a liquid medium.

So if you were thinking of maybe having an untethered robot that could, say, move in our ambient environment either to work in a factory or perhaps go in a water stream to sense a source of pollution and neutralise whatever toxin it was in that environment, that’s the sort of thing where you might want to think about using cells from an insect or maybe cells from bacteria. And those are all certainly very valid and useful applications.

Where do you hope this research will lead?

My focus always returns to medical implants because I think one of the biggest trends that we see in medicine today is this idea of precision medicine or personalised medicine.

From experience, we know that different cancer patients can go into a clinic and get essentially the same therapy, with some people responding really well to the treatment and yet other people don’t.

Rather than giving everyone the same medicine, why not give them an implant that can generate the chemicals that their body needs, or sense that this person needs a little bit more at this time, or that person doesn’t.

If we place certain cells that secrete insulin in a diabetic, for example, these cells could potentially automatically regulate how much insulin they’re secreting for the needs of that individual person at that time.

I think the most interesting thing that I’m doing right now, is working towards using the skeletal muscle that I’ve developed in the lab as a potential implant to replace skeletal muscle that’s been lost due to disease or damage.

This is something that I just think is a really meaningful cause. It matters a lot to me. I think mobility is something that a lot of us take for granted. And when you lose it, it can have a significant impact on the quality of your life.

A lot of a lot of people have tried to do this over the years, and we’ve understood a lot by building these robots. How do you tune it to respond to its environment and how you generate really, really large forces from compact volumes? I would love to be able to contribute any small part to helping restore the mobility to somebody who’s lost it.

- This article first appeared inissue 353ofBBC Science Focus–find out how to subscribe here