Chocolate is made from the beans ofTheobroma cacao, a small evergreen tree native to the rainforests of Central and South America. Translating as ‘food of the Gods’ in Greek, its elongated pods grow up to 35cm and vary in colour from bright yellow to deep purple.

Archaeological evidence - traces of cacao on ancient pottery - suggests we’ve been indulging in cacao products for as long as 5,300 years (3,300 BC). The Mayans, indigenous people of Central America and Mexico, enjoyed it as a thick, foamy, bitter drink and the beans were potentially even used as currency by the years 250 - 900.

The beans were so revered that the Aztecs (circa 1345 - 1521) believed that cacao was a gift from the god Quetzalcoatl. They continued the Mayan tradition of preparing cacao as a drink, and it was enjoyed by rulers, priests and noblemen. Cacao was consumed for a variety of purposes including medicinal and as an aphrodisiac, and formed part of the rations supplied to Aztec soldiers. On special occasions, such as weddings, even lower-class members of society would be treated to a sip of the divine drink.

Today, cacao is grown commercially grown in the tropical zones around the equator where climate conditions are well suited for their finicky nature; high temperatures, plenty of rainfall and moist air, while the rainforest canopy provides shade and protection from the wind.

1. Growing

TheTheobroma cacao tree bears flowers in small groups along the trunk and lower main branches. Once pollinated, these flowers develop into berries, called ‘pods’. The pods take around five or six months to mature and ripen, turning a yellowy-orange colour as they do so.

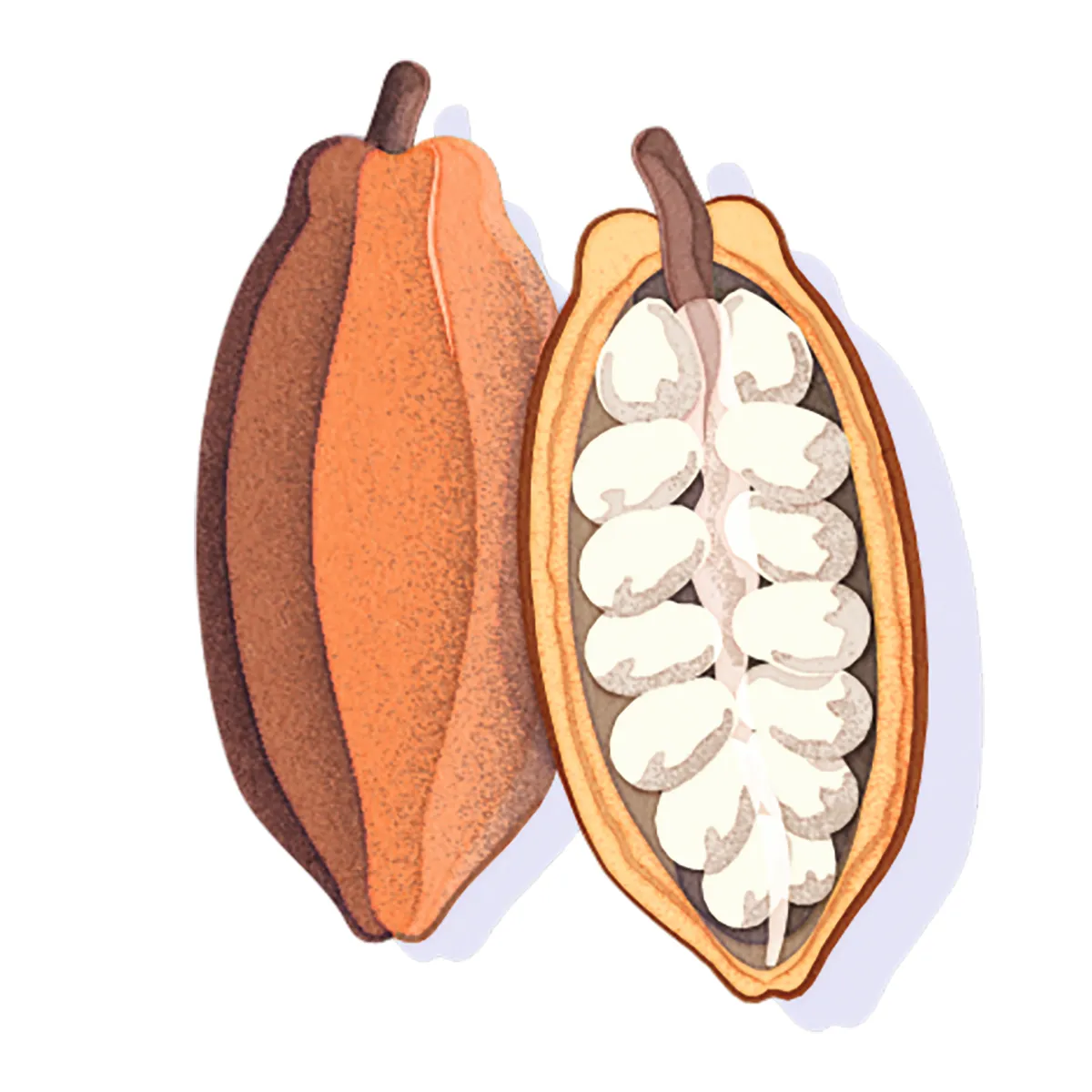

2. Splitting

The elongated pods are harvested by hand and split open to reveal between 20 to 60 oval beans arranged along the long axis in a sweet, white, mucilaginous pulp. This usually happens on the same day as they are harvested, or at least within a few days.

If you want to, you can eat the cacao beans raw. The beans themselves have an intense, bitter, somewhat earthy flavour, and are a purple-brown colour on the inside.

The white pulp that surrounds the beans has a very complex flavour: it's much sweeter and fruitier, with a hint of citrus.

3. Fermenting

The pulp and the beans are scooped out of the pods, and the beans are separated from the placenta. Careful fermentation develops the flavour by microbial succession.

First, the yeasts react, then the lactic acid bacteria, and finally the acetic bacteria. The fermentation process essentially modifies the beans and eliminates the mucilage, changing the colour, taste and smell of the beans.

4. Drying

The beans are dried to remove the moisture content. Traditionally, this is done naturally by the Sun, and the drying process continues to develop the flavour. Drying the beans quickly will result in a more bitter taste, but careful moderation will allow volatile acetic acid to evaporate during the drying process, resulting in a less acidic (and more pleasant) taste.

5. Roasting

Roasting develops the flavour further, and also sterilises thebeans, killing microorganisms (like bacteria) on the outer shell. Successful fermentation is an important microbial process, and will naturally create conditions ideal for bacteria, fungi and mould, so roasting is essential to remove these potentially dangerous pathogens.

Roasting also helps to get rid of some of the lingering acidic flavours, and makes the next stage much easier.

6. Cracking

The roasted beans are cracked by applying pressure with a cacao crusher, separating the husks from the beans.

7. Winnowing

Winnowing removes the lighter husks and dust particles, leaving the heavier beans or ‘nibs’.

Originally, winnowing was done by hand in a winnowing basket. The beans would be tossed into the air before being caught again in the basket, causing the brittle shells to break apart and separate from the beans. If done outside on a windy day, the lighter shells would blow away and the heavier nibs would fall back into the basket. Clever!

Today, it's mostly done by a winnower machine. Vibrating shelves shake the beans, causing them to fall through a series of screens before a vacuum removes the lighter shells, leaving the precious nibs ready for the next stage.

8. Grinding

The now shell-less beans are ground up, and sugar is added. Cacao nibs are naturally quite bitter with a strong flavour, so adding sugar makes them sweeter.

Adding sugar was a later development in the production of chocolate, having come about in the 16th Century, after the beans arrived in Spain.

9. Tempering

Slowly heating and cooling the chocolate allows the fats to crystallise uniformly and the chocolate to break with a satisfying snap. It also helps give chocolate that smooth and glossy finish.

10. Moulding

The mixture is poured into a mould where it cools, before being packaged and shipped off to distribution centres ready for eating.

Read more:

- Which chocolate is healthiest to binge on: milk, dark or white?

- Why does chocolate make us happy?

- When I make chocolate chip cookies, why don’t the chocolate chips melt in the oven?

- Does eating chocolate give you spots?

To submit your questions email us at questions@sciencefocus.com (don't forget to include your name and location)